Advantage of Enameled Copper Wire

![DLX DLX]()

About DLX ALLOY

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

![DLX DLX]()

![DLX DLX]()

Advantage of DLX ALLOY

1.Market Leader - Top 5 in China's nonferrous metal industry

2.Flexible products - Thousands of product specifications,Meet multiple needs of buyers

3.Low MOQ - Can customize samples

4.Short production lead time,fast delivery of whole cabinet

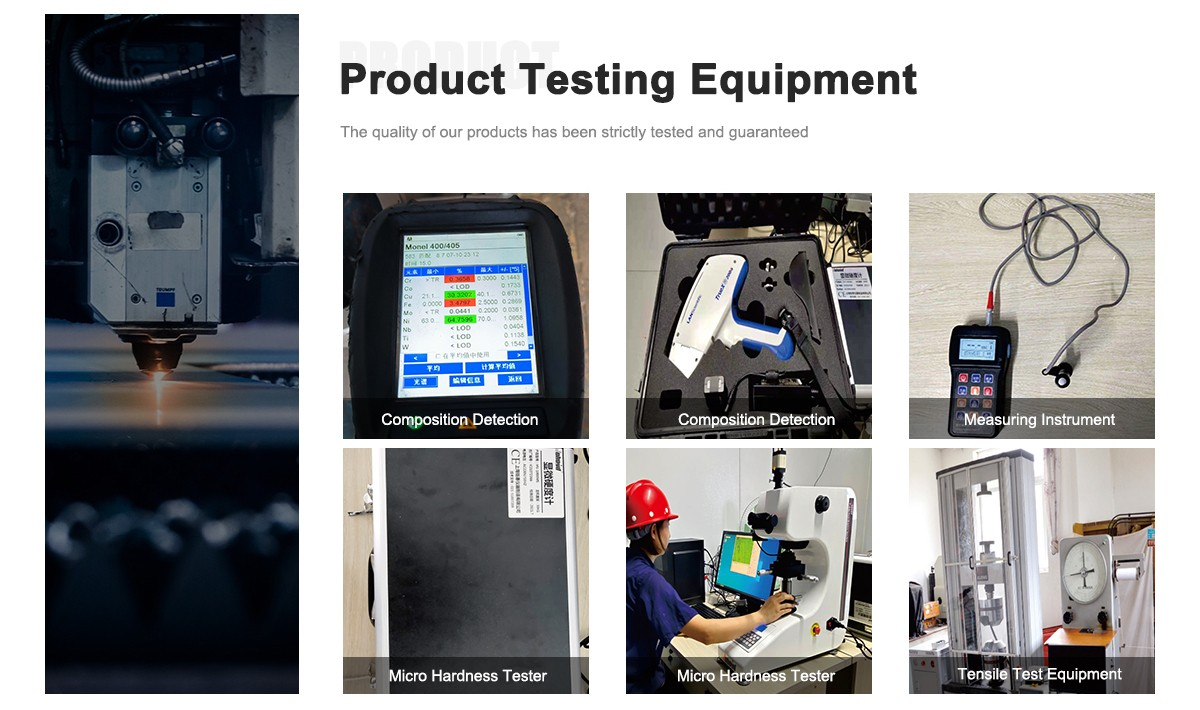

5.Professional inspection equipment - Before delivery, we will use spectrometers, tensile testers and other professional equipment to conduct a comprehensive inspection of the products to ensure that the goods are qualified for acceptance

6.Professional business team - Quickly responds to customer inquiries,24-hour professional quotation online The salesperson will follow the customer's requirements for the use of the product,Professionally recommend more appropriate performance and price products to customers

7.Intact packaging - Packaging according to customer needs.You can customize wooden boxes to ensure that the goods arrive at the destination in good condition

8.Various payment methods - Facilitate customer payment

9.Get good reviews from customers - Old customers have long-term cooperation,The longest is more than 7 years

10.Received various awards - Google is very recognized by us,They give us awards every year

![DLX DLX]()

![incoloy incoloy]()