Overview

![nickel welding wire nickel welding wire]()

Description of Nickel Welding Wire ERNiCrMo-3 ERNiCrMo-4

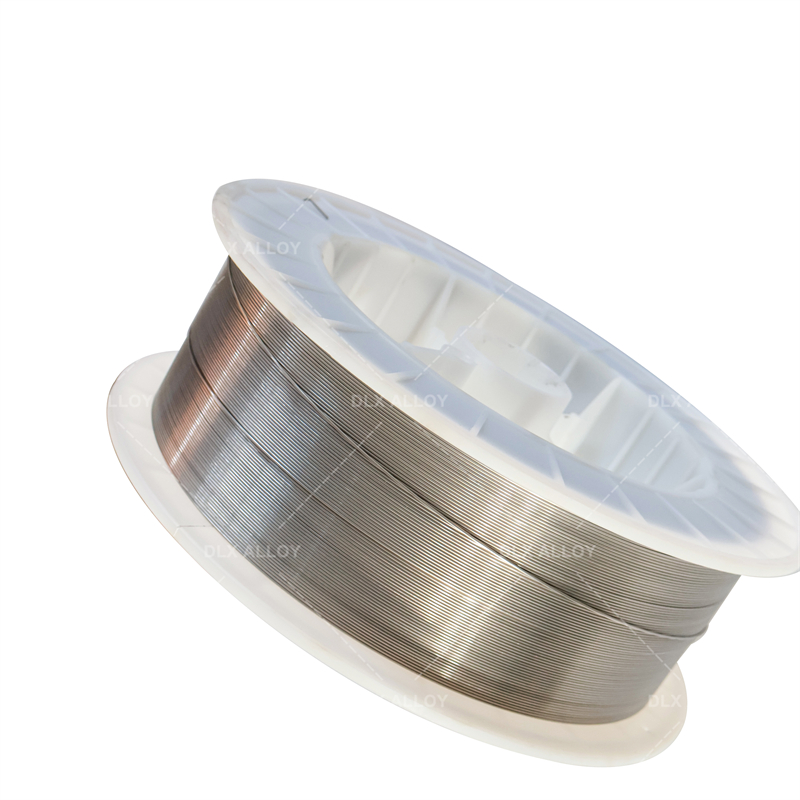

Nickel Welding Wire ERNiCrMo-3 ERNiCrMo-4 has good resistance to corrosion and high temperature,and has high strength and good fabricability.it is widely used in petrochemical, metallurgy, atomic energy, ocean development, aviation, aerospace and other industries.

As a reliable manufacturer and supplier, DLX Alloy provides wholesale Nickel Welding Wire ERNiCrMo-3 ERNiCrMo-4 at cost-effective prices, offering bulk discounts and global shipping to ensure superior quality, reliability, and durability for industrial applications.

Material Overview : Nickel Welding Wire ERNiCrMo-3 ERNiCrMo-4 is a nickel-chromium-molybdenum alloy with the addition of iron and tungsten, making it highly resistant to oxidation, pitting, crevice corrosion, and stress corrosion cracking. It is specifically designed for welding applications in aggressive chemical environments.

![product details (2) product details (2)]()

![comparison comparison]()

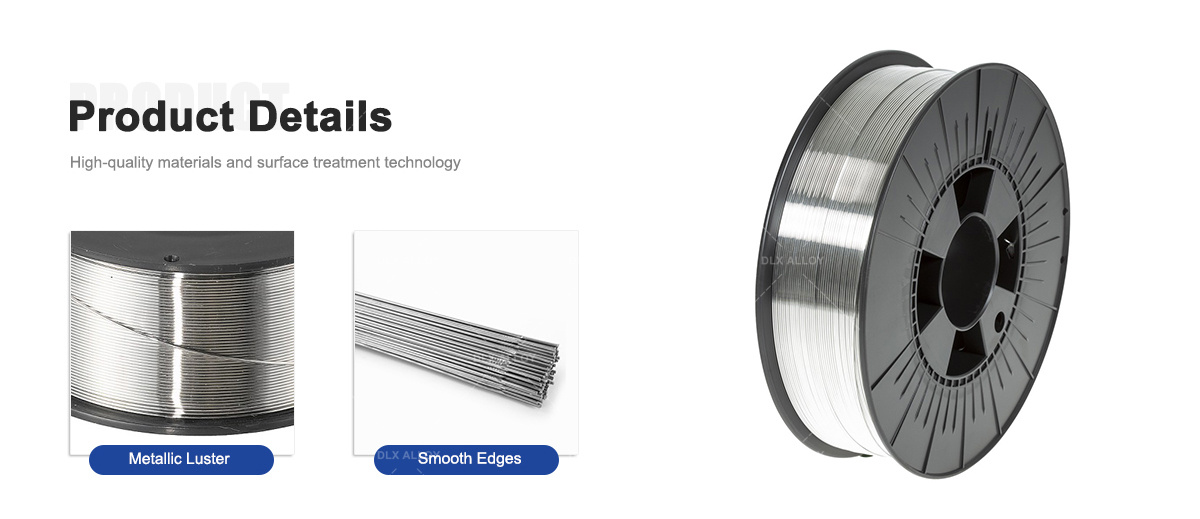

Feature of Nickel Welding Wire ERNiCrMo-3 ERNiCrMo-4

✔Outstanding Corrosion Resistance

Performs exceptionally well in acidic, oxidizing, and chloride-rich environments.

✔ High-Temperature Strength

Maintains mechanical stability in extreme heat up to 1093°C (2000°F).

✔ Excellent Weldability

Ensures smooth, crack-free, and defect-free welds.

✔ Chemical & Acid Resistance

Resistant to hydrochloric acid, sulfuric acid, nitric acid, and seawater corrosion.

✔ Long-Lasting Performance

Built for tough industrial settings, offering extended service life and reliability.

Video of ERNiCrMo-3 Mig Welding Wire

DLX Alloy's Nickel Welding Wire ERNiCrMo-3 ERNiCrMo-4 delivers superior weld performance for critical sectors like aerospace and petrochemical. Offering competitive wholesale pricing, bulk discounts, and worldwide shipping, DLX Alloy provides high-quality, dependable Nickel Welding Wire solutions customized for your industrial requirements.