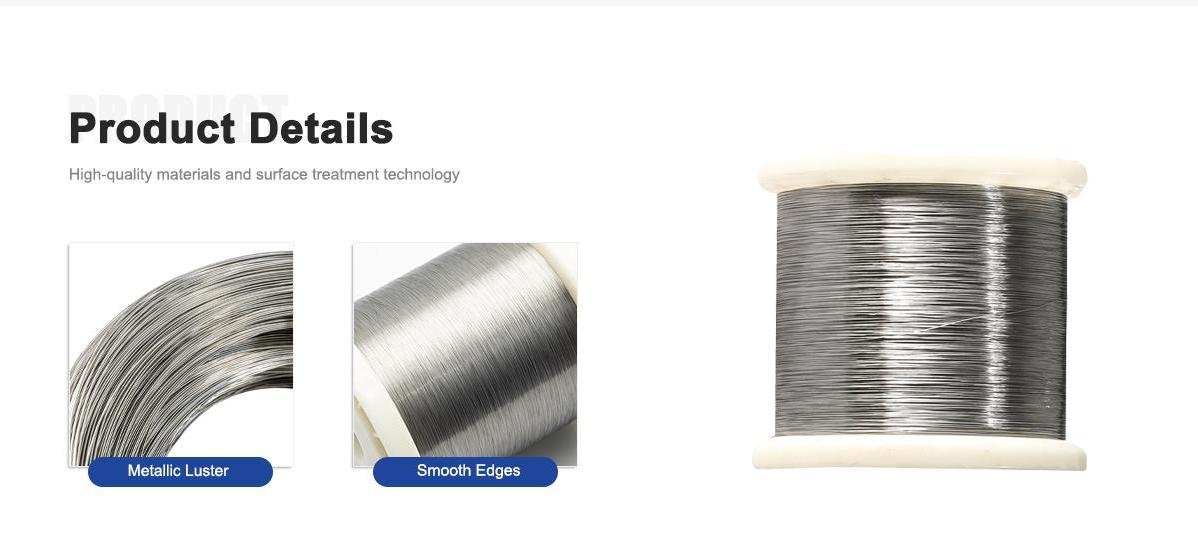

Discover our custom Monel 400 spring wire, a top-tier nickel-copper alloy designed specifically for demanding applications where corrosion resistance and mechanical strength are paramount. This high-quality wire excels in harsh environments, offering exceptional performance against seawater, acids, and alkalis.

Monel 400, Monel K500

DLX

black/Bright

Customized

415

ISO9001

3kg

5-20 Days

Industry, Construction,Boiler Pipe

Nickel

| Availability: | |

|---|---|

Product Description

Monel 400 spring wire is a specialized nickel-based alloy renowned for its outstanding corrosion resistance and high tensile strength, making it indispensable in harsh environmental applications. Composed primarily of nickel (63-70%) and copper (28-34%), with traces of iron and manganese, this material maintains structural integrity in temperatures ranging from sub-zero to over 1000°F. Our custom Monel 400 wire is tailored for precision springs, offering superior elasticity and fatigue resistance. Whether for marine engineering, chemical processing, or aerospace components, this durable alloy wire stands out as a cost-effective alternative to stainless steel in corrosive settings, ensuring longevity and reduced maintenance costs.

Monel 400 alloy wire withstands exposure to saltwater, acids, and alkaline solutions, ideal for marine and chemical industry springs.

Boasting tensile strengths up to 1100 MPa, this nickel alloy spring material provides excellent spring-back properties and fatigue endurance.

Operates effectively from -200°F to 1000°F, making it suitable for cryogenic and high-heat applications in harsh environmental wire solutions.

Available in various diameters (0.1mm to 5mm) and surface treatments like bright annealed or coated, ensuring precise fit for bespoke Monel wire fabrication.

Low magnetic permeability enhances suitability in electronic and instrumentation springs within corrosive nickel alloy environments.

Easily formed into complex spring shapes without compromising strength, supporting efficient custom Monel 400 wire production.

Specification

| Name | Monel 400(N04400) | Monel K500(N05500) | |

|

Chemmical

Composition wt.

|

Ni | 63.0-67.0 | 63.0-67.0 |

| Fe | ≤2.00 | ≤2.00 | |

| C | ≤0.03 | ≤0.25 | |

| Mn | ≤1.50 | ≤0.15 | |

| P | - | - | |

| Si | ≤0.50 | ≤1.00 | |

| Cu | 28.0-34.0 | margin | |

| S | - | ≤0.01 | |

| Cr | - | - | |

| Al | - | 2.0-4.0 | |

| TI | - | 0.25-1.00 | |

| Others | - | - |

| Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation | HB |

| Monel K500 | 8.05 g/cm3 | 1288-1343°C | 1100 | 790 | 20% | - |

| Monel 400 | 8.83 g/cm3 | 1300-1390°C | 480 | 170 | 35% | >331 |

Application Field

Monel Alloy Wire is used in various applications due to its corrosion resistance and strength. Here are five key application fields:

Utilized in valve springs, fasteners, and pump components for seawater-resistant applications, preventing corrosion in harsh oceanic environments.

Ideal for springs in reactors, heat exchangers, and piping systems exposed to acids and caustics, enhancing durability in corrosive chemical alloy wire setups.

Employed in high-strength springs for landing gear and instrumentation, offering reliability in extreme temperature and pressure conditions.

Perfect for downhole tools and valve springs in harsh environmental settings, resisting hydrogen sulfide and chloride-induced stress cracking.

Used in non-magnetic springs for sensors and switches, providing stable performance in humid or corrosive industrial wire applications.

Incorporated into custom springs for equipment requiring biocompatibility and resistance to sterilizing agents in harsh sanitary environments.

Our Advantage

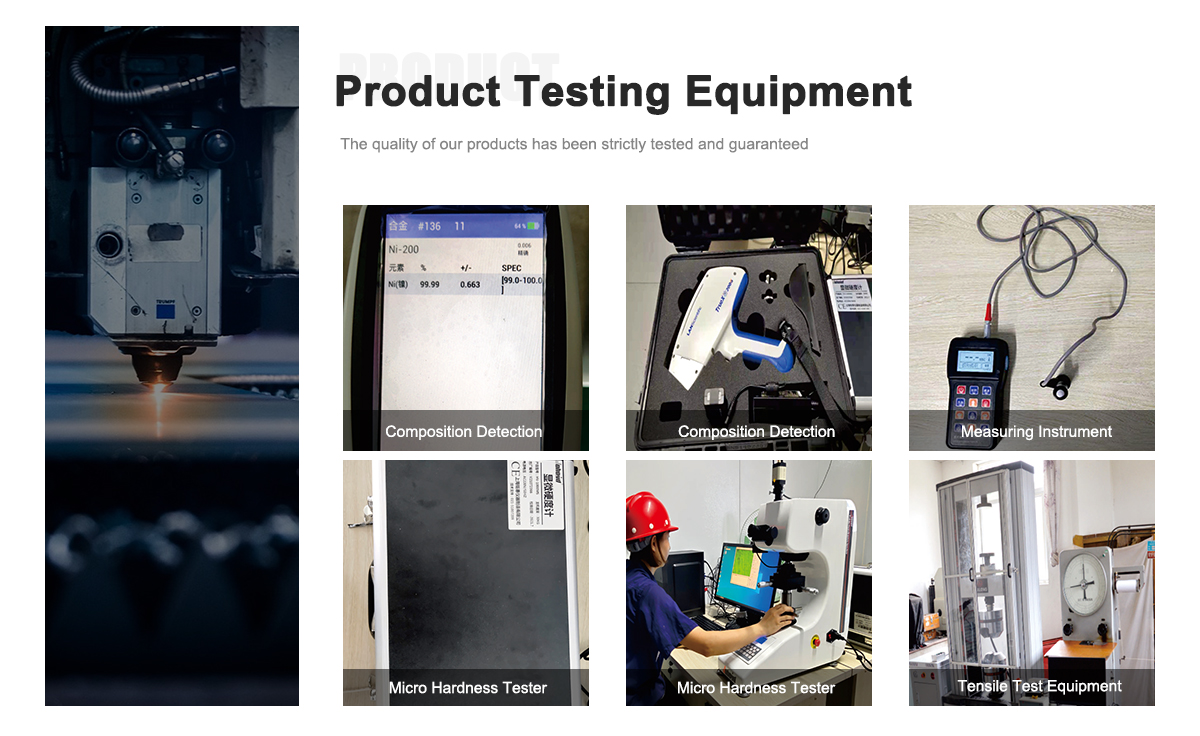

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO 9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

FAQ

Monel 400 is a nickel-copper alloy with superior corrosion resistance to seawater, acids, and high temperatures, ensuring long-term performance in extreme conditions unlike standard stainless steel wire.

Yes, we offer fully customizable diameters, lengths, and tensile strengths to meet specific industrial needs, with options for bulk Monel wire suppliers and rapid prototyping.

Monel 400 provides excellent cost-effectiveness for marine and chemical applications, with better ductility than Inconel, though Hastelloy may be preferred for ultra-acidic environments in custom alloy spring fabrication.

It performs reliably from -200°F to 1000°F, making it versatile for cryogenic storage and high-heat processing in harsh environmental industrial settings.

Monel 400 is generally non-magnetic at room temperature, which is advantageous for electronic and precision instrumentation springs in non-ferrous alloy wire uses.

Look for certifications like ASTM B164 compliance, and choose reputable Monel wire suppliers offering material testing reports for corrosion resistance and mechanical properties.

| dlx-group@dlx-alloy.com | |

| Phone | 0086-13218680935 |

| Address | NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China |