FAQs of Cr20Ni80 Thermal Spray Wire

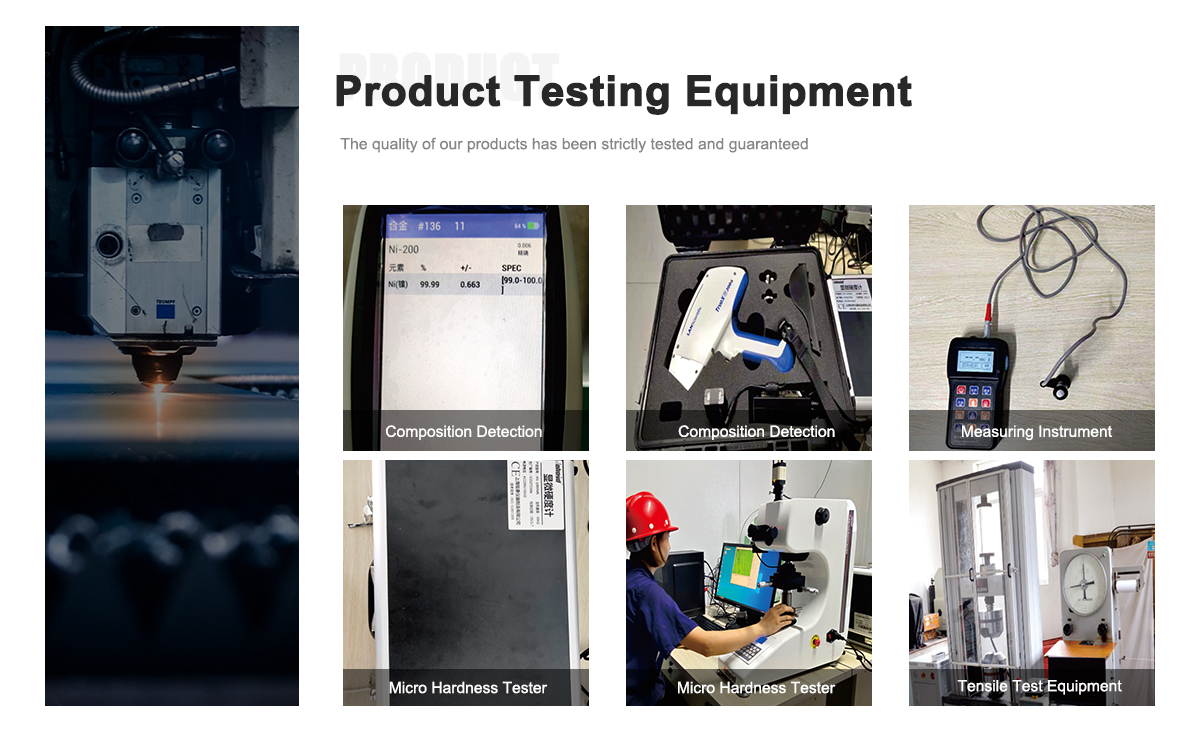

1.Why Choose Our Cr20Ni80 Thermal Spray Wire?

Factory Direct Supply with Competitive Wholesale Prices

Custom Sizes & Large Stock Availability

Fast Global Shipping & Reliable Industrial Supply

Guaranteed High Purity for Electronic & Industrial Applications

2. How Long Is the Delivery Time for Cr20Ni80 Thermal Spray Wire?

Delivery for Cr20Ni80 Thermal Spray Wire typically takes 10-30 days for small orders, while large orders require up to 60 days, depending on quantity and specifications.

3. Do You Accept OEM/ODM for Cr20Ni80 Thermal Spray Wire?

Yes, we fully support OEM/ODM production for DLX Thermal Spray Wires—simply send your samples or drawings for customized manufacturing solutions.

4. What Are the Payment Terms for Buying Cr20Ni80 Thermal Spray Wire?

We accept flexible payment terms for Cr20Ni80 Thermal Spray Wire orders, including T/T, L/C, D/A, D/P, Western Union, MoneyGram, and PayPal.

5. Can I Visit Your Factory Before Ordering Cr20Ni80 Thermal Spray Wire?

Yes, you're welcome to visit our DLX Thermal Spray Wires production facility—we're excited to build partnerships through in-person meetings.

6. Where Is Your Cr20Ni80 Thermal Spray Wire Production Base Located?

DLX Thermal Spray Wires are manufactured in Jiangsu, China, with efficient global shipping based on your order quantity and specific requirements.

7. Can You Send Cr20Ni80 Thermal Spray Wire Samples?

Yes, we provide free DLX Thermal Spray Wires samples to help you evaluate quality and performance before bulk purchase.

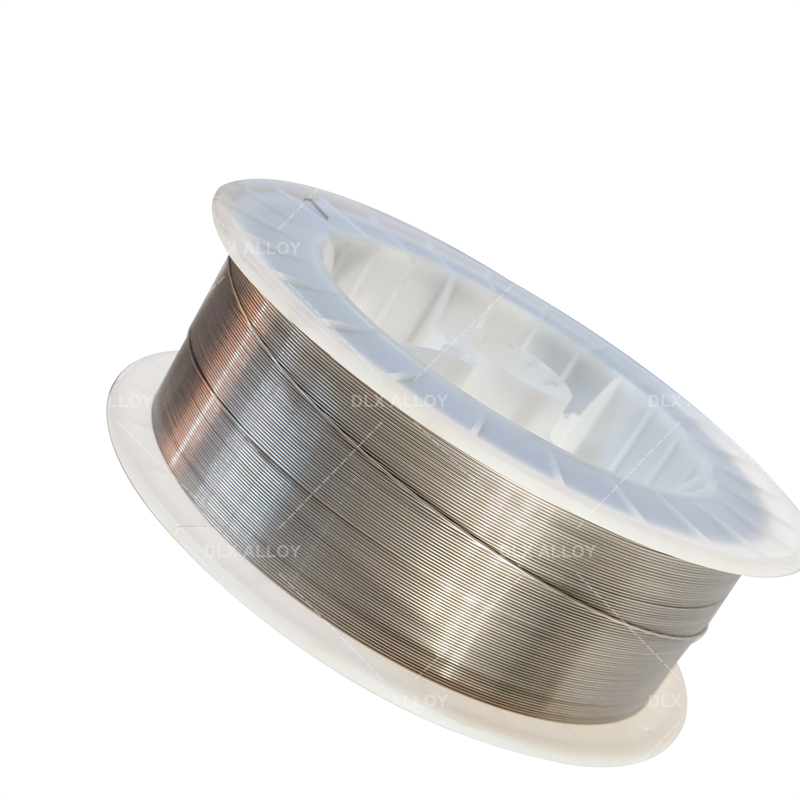

![THERMAL SPRAY WIRE THERMAL SPRAY WIRE]()