FAQs of Inconel 625 Sheet/Plate

1.Why Choose Our Inconel 625 Sheet/Plate?

Factory Direct Supply with Competitive Wholesale Prices

Custom Sizes & Large Stock Availability

Fast Global Shipping & Reliable Industrial Supply

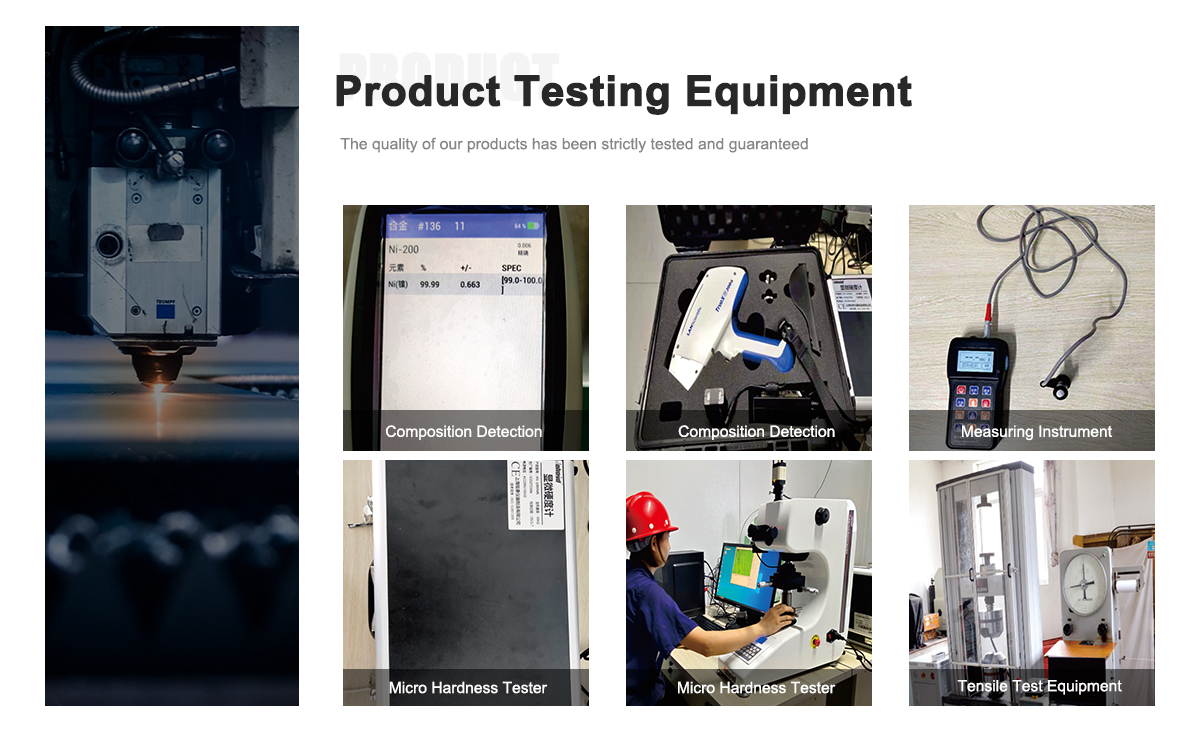

Guaranteed High Purity for Electronic & Industrial Applications

2. How Long Is the Delivery Time for Inconel 625 Sheet/Plate?

Delivery for Inconel 601 Pipe typically takes 10-30 days for small orders, depending on quantity. Large orders may require up to 60 days for production and shipping.

3. Do You Accept OEM/ODM Production for Inconel 625 Sheet/Plate?

Yes, we accept OEM/ODM production for Inconel 625 Sheet/Plate. Simply send us your samples or drawings to get started.

4. How Do You Handle Pre-Sale and After-Sale Service for Inconel 625 Sheet/Plate?

Our professional team offers one-on-one support for pre-sale consultations and after-sale queries on Inconel 625 Sheet/Plate. We're here to ensure your needs are fully met.

5. Can I Visit Your Factory Before Ordering Inconel 625 Sheet/Plate?

Yes, you're welcome to visit our factory before ordering Inconel 625 Sheet/Plate. It's a great opportunity to connect and discuss your requirements.

6. Where Is Your Production Base for Inconel 625 Sheet/Plate?

Our production base for Inconel 625 Sheet/Plate is in Jiangsu, China, with efficient shipping worldwide based on your order size and specs.

7. Can You Send Samples of Inconel 625 Sheet/Plate?

Yes, we can send samples of Inconel 625 Sheet/Plate for your evaluation. Contact us to arrange.

![INCONEL PLATE INCONEL PLATE]()