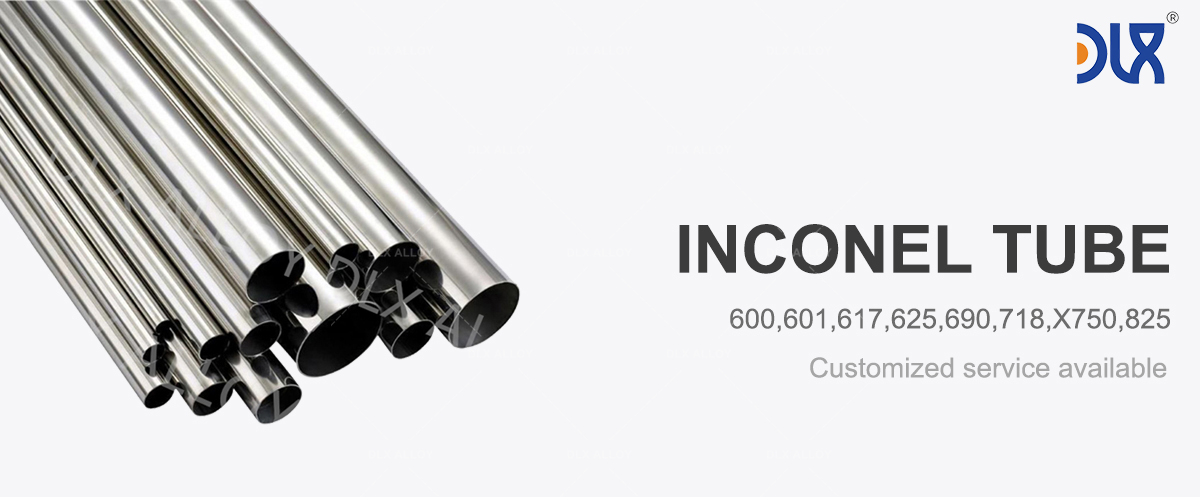

Description of Inconel Tube Nickel 625 718

![inconel tube inconel tube]()

Inconel Tube Nickel 625 718 is a Nickel-Chromium-Molybdenum alloy with excellent corrosion resistance in a wide range of corrosive media, being especially resistant to crevice and corrosion pitting. Inconel Tube is a good choice for sea water applications.

Inconel Tube Nickel 625 718 is favourable for general production of components where designs call for high resistance to temperature and corrosion and applications include turbine, heat exchanger and moulding components. Inconel 625 Nickel Seamless Tube are widely used and specified for components in the offshore chemical processing, oil and gas and nuclear industries.

Inconel Tube Nickel 625 718 also known for its great resistance to pitting, stress corrosion, crevice corrosion, corrosion fatigue and erosion corrosion which helps to to maintain its mechanical properties.

![product detail product detail]()

![DLX DLX]()

Feature of Inconel Tube Nickel 625 718

1. Superior Corrosion Resistance.

Inconel Tube Nickel 625 718 resists pitting, crevice corrosion, and oxidation in harsh environments, including seawater and acidic conditions.

2. High Strength and Toughness.

Offers exceptional tensile strength and toughness across a wide temperature range, ensuring structural integrity under extreme stress.

3. Excellent High-Temperature Performance.

Maintains mechanical properties at elevated temperatures up to 980°C, ideal for high-heat applications like gas turbines and heat exchangers.

4. Seamless Design for Reliability.

Its seamless construction eliminates weak points, providing uniform strength and resistance to pressure in critical systems.

5. Versatile Weldability.

Exhibits excellent weldability without susceptibility to post-weld cracking, allowing for easy integration into complex assemblies.

Video of Inconel Tube Nickel 625 718